Top 15 Leading Lithium-Ion Battery Manufacturers in China

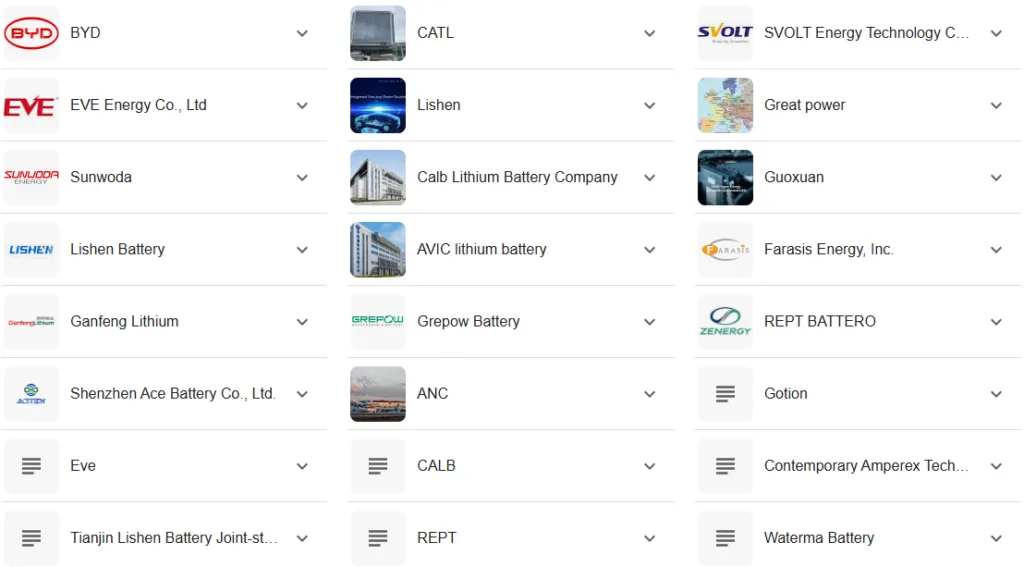

China’s Top 15 Lithium-Ion Battery Manufacturers (2025)

China dominates the global lithium-ion battery market, supplying ~70% of worldwide capacity and housing innovation leaders driving the energy transition. From EVs to grid-scale storage, these manufacturers combine cutting-edge tech, massive scale, and aggressive global expansion. Here are the top 15 shaping the future:

⚡ China’s Top 15 Lithium-Ion Battery Manufacturers (2025)

| Rank | Manufacturer | Key Strength | HQ Location |

|---|---|---|---|

| 1 | CATL | Global market share (38.1%), tech innovation | Fujian |

| 2 | BYD (FinDreams) | Vertical integration, Blade Battery | Shenzhen |

| 3 | EVE Energy | Diversified portfolio (power/energy storage) | Huizhou |

| 4 | CALB | Aviation/solid-state R&D | Changzhou |

| 5 | Gotion High-tech | VW partnership, low-temp performance | Hefei |

| 6-15 | REPT, SVOLT, coolithium, etc. | Emerging tech, global expansion | Nationwide |

🔋 Top 5 Manufacturers: Tech, Scale & Strategy

- CATL (Contemporary Amperex Technology)

- Dominance: 38.1% global market share (152.7 GWh installed Jan-May 2025), supplying Tesla, BMW, and Volkswagen.

- Innovation: 3rd-gen CTP tech boosts energy density to 255 Wh/kg and enables 15-minute ultra-fast charging. Its “zero-carbon factory” sets industry sustainability benchmarks.

- Global Reach: Plants in Germany (14 GWh), Hungary, and Indonesia (40 GWh for储能) cement local supply chains.

- BYD (FinDreams Battery)

- Blade Battery Breakthrough: Structural LFP design increases space utilization by 50% and passes rigorous nail penetration tests—setting safety standards .

- Vertical Control: Mines raw materials to finished packs, enabling cost leadership.储能 growth exceeds 50% yearly, backed by projects like Saudi Arabia’s 15.1 GWh mega-storage.

- Tesla Tie-Up: Supplies LFP cells for Model 3/Y, leveraging price advantages over Western rivals.

- EVE Energy

- Triple-Threat Strategy: Balances consumer electronics, EV batteries, and储能 (26.29 GWh shipped in 2023, up 121% YoY).

- Global Partnerships: Collaborates with Tesla on 4680 cell production; signs 50 GWh supply deals (e.g., HyperStrong).

- Footprint: Malaysian factory (20 GWh) targets Southeast Asia; Hungarian plant supports European EV/ESS demand.

- CALB (China Aviation Lithium Battery)

- High-End R&D: Develops 400 Wh/kg solid-state samples and aviation-grade cells. Revenue surged 32.5% YoY (2023).

- EV Focus: Powers NIO, XPeng, and other NEVs. Expanding in Europe to challenge LG/Samsung.

- Gotion High-tech

- VW-Backed Scale: Volkswagen owns 25% stake. Global R&D centers (US/Germany/Japan) drive low-temperature batteries (-30℃, 85% capacity) 46.

- Aggressive Globalization: US/Thai/Vietnamese factories; German plant supplies “Made in EU”储能 cabinets.

📊 Why Chinese Giants Lead: Strengths vs. Challenges

Advantages Driving Dominance:

- Supply Chain Control: CATL/BYD mine lithium, refine materials, and recycle cells—slashing costs by 15–20% vs. Western peers.

- Policy Support: Subsidies for NEVs and national储能 targets (e.g., 30% renewable energy by 2030) fuel demand.

- Tech Agility: From CATL’s cobalt-free batteries to BYD’s Blade, innovation cycles are 2–3× faster than global rivals.

Critical Challenges:

- Overcapacity: Domestic产能 utilization fell to 65% (2024), triggering price wars and margin erosion.

- Trade Barriers: The US IRA excludes Chinese batteries; EU carbon taxes add 8–10% costs for non-localized production.

- Resource Dependence: 60% of lithium/镍imported—volatile prices threaten profitability.

🚀 Rising Stars (#6–15): Specialists & Global Challengers

- Hithium (海辰储能): Pure-play储能 leader; shipped 16 GWh globally (2024). Partnered with Samsung for 10 GWh projects.

- SVOLT (蜂巢能源): 110% YoY growth—supplies Stellantis/BMW. LFP cells dominate European commercial EVs.

- Sunwoda (欣旺达): iPhone battery supplier pivoting to EVs. Building Moroccan/Hungarian plants for EU localization.

- REPT Battero (瑞浦兰钧): Launched 688 Ah储能 cell with 6.9 MWh systems—pushing “big capacity” frontiers.

🔮 Future Trends: Solid-State, Globalization & Consolidation

- Next-Gen Tech: CATL/Gotion target all-solid-state batteries by 2030. CALB’s 400 Wh/kg prototypes lead R&D.

- Capacity Wars: 500+ Ah cells will dominate grid storage by 2026. CATL/EVE plan 600 GWh global产能 by 2030.

- Survival Shakeup: Experts predict 70% of China’s 200+ battery firms will merge or exit by 2030 amid funding squeezes.

“China turned batteries from commodities into strategic assets. Their manufacturers don’t just scale—they set tech paradigms.” — Energy Storage Journal, 2025.

From CATL’s unshakable scale to Hithium’s储能 focus, these 15 giants blend innovation, state backing, and ruthless efficiency. As solid-state and钠-ion emerge, their battle isn’t just for market share—it’s to define global energy’s next era.